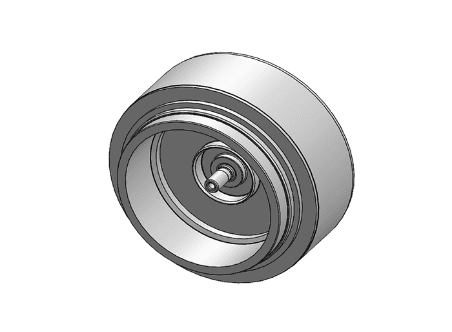

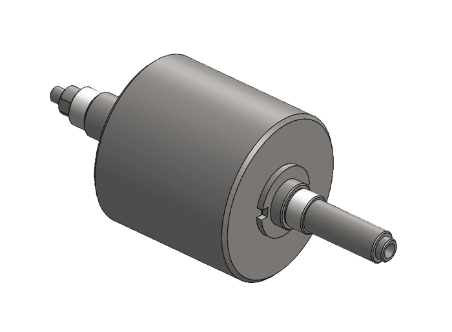

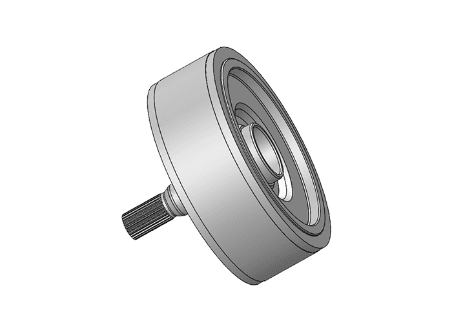

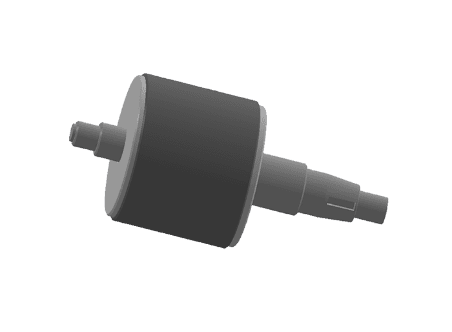

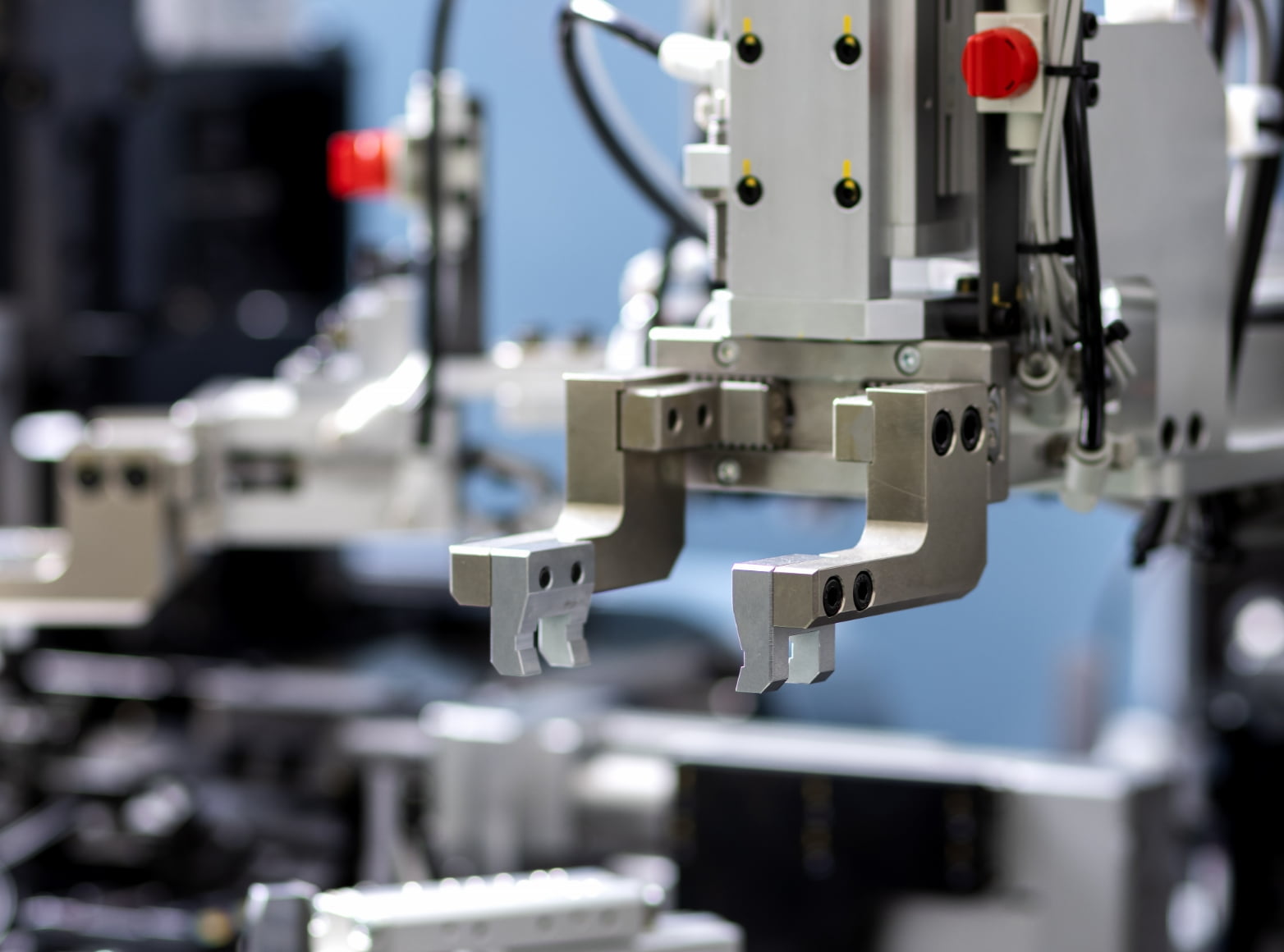

Workpiece example

Custom-made machines

for a wide range of workpieces

DSK offers products for a wide range of workpieces, from large to small.

The target fields also range from automotive parts to home appliances and power tools, all of which require a high precision and balance.

Therefore, for many years, we have based our business on the principle of "custom-made machine" to meet the needs of our customers.

Based on the skills and knowledge we have cultivated over the years, we understand every detail of our customer's requirements and are always one step ahead of the curve.

We will continue to rise to the challenge of thoroughly addressing each and every manufacturing process while cherishing the bond with our customers.

We can help you

with these issues and concerns

-

Consultation on balance measurement and correction

in the development and improvement of workpieces -

Balance measurement and

correction of workpieces

for test purposesIf a special tool is required or the test quantity is large, we may charge a fee for this service.

-

Stable operation and

simple maintenance

at overseas factories

Line up

"Workpiece" x "Cutter"

Cutting Tools Lineup

DSK offers various machines for balance measurement and correction to accommodate a wide variety of customer's workpieces.

In addition to the basic cutting methods using several types of cutters and drills to correct unbalance, we can also customize our cutting methods to the desired correction method for the customer's product.

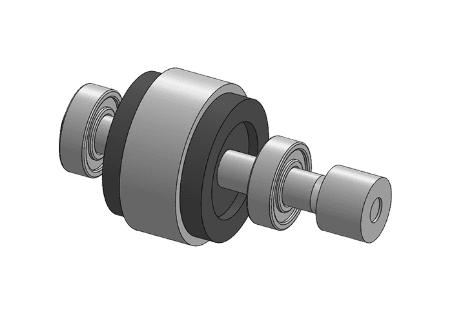

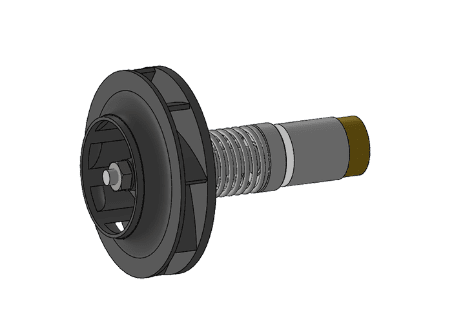

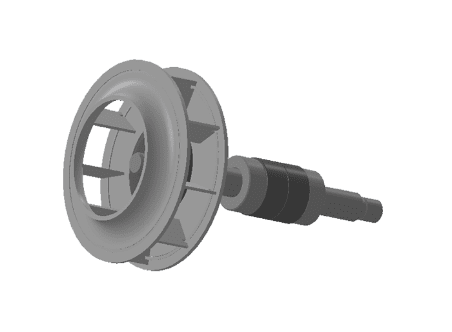

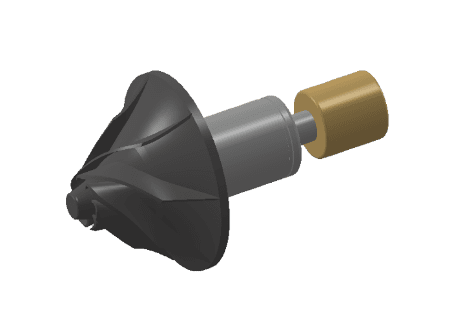

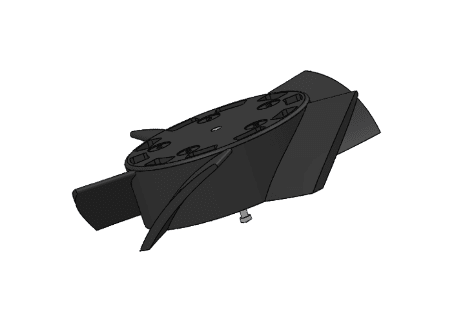

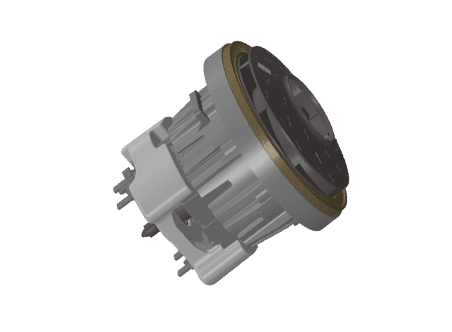

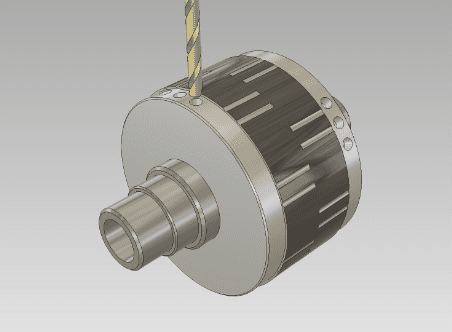

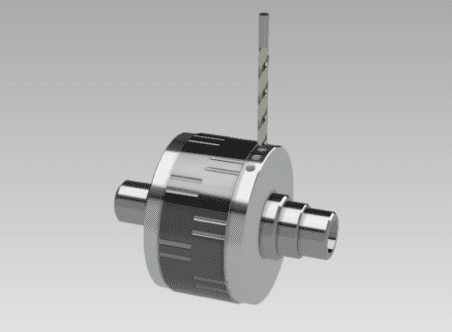

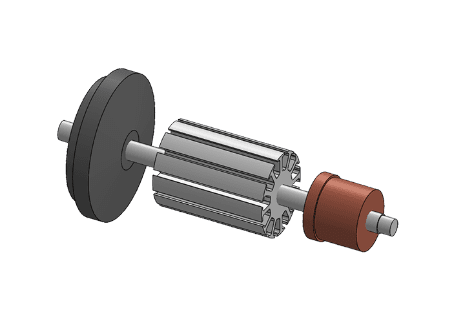

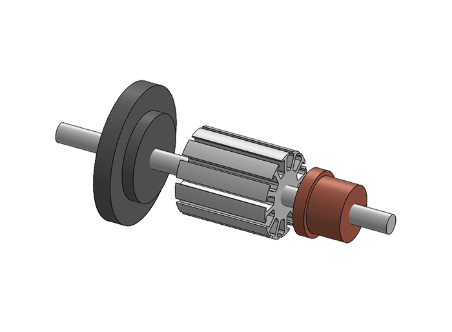

01Workpiece Examples

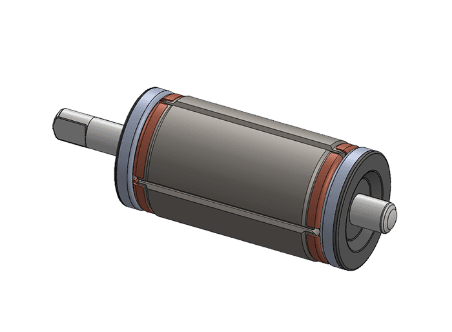

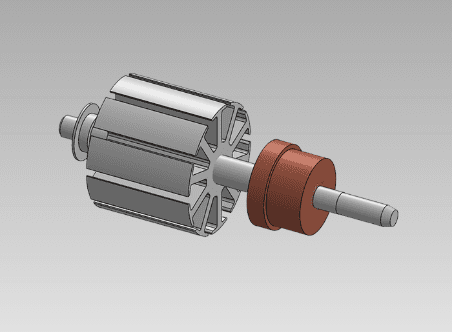

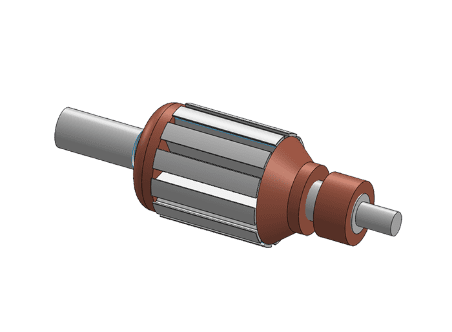

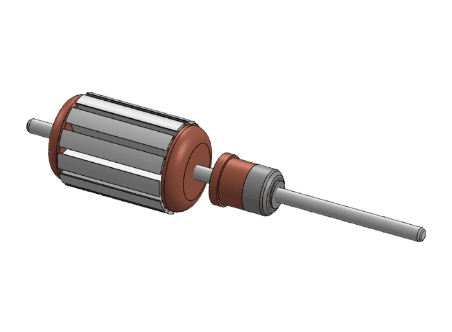

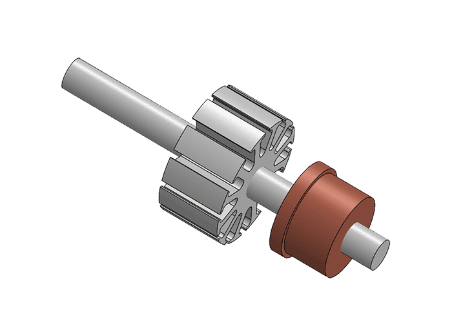

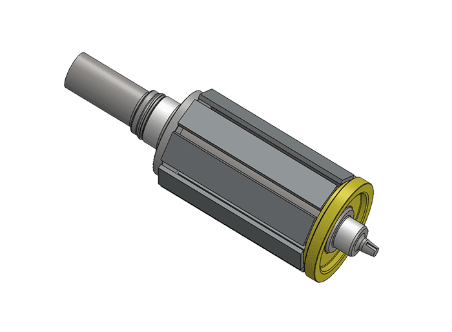

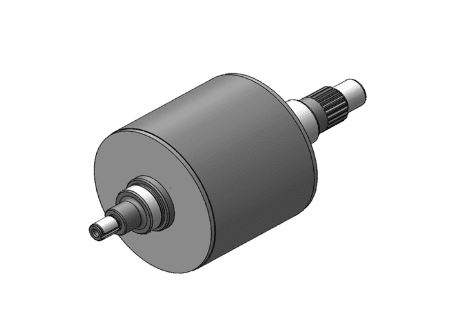

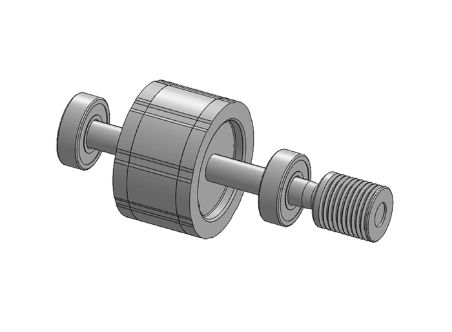

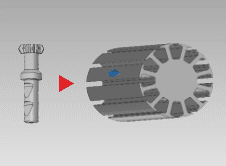

DSK machines are designed for a variety of workpieces and can handle multiple workpieces with different shapes.

Even when switching to a different workpiece model, measurement and correction can be performed with stable accuracy, improving work efficiency.

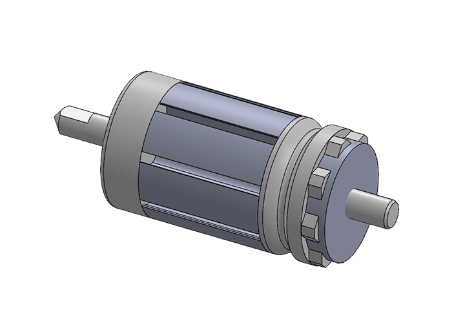

EV motor

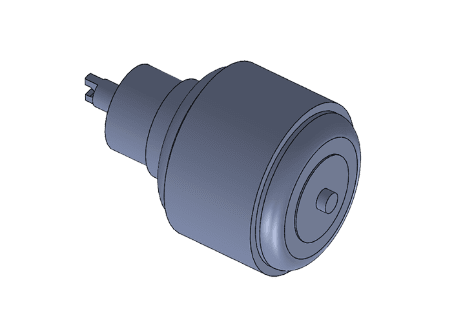

Starter motor

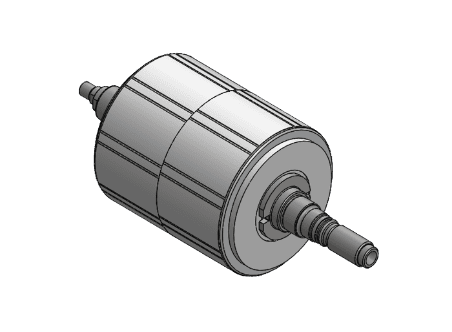

Fuel pump motor

Wiper motor, Power window motor

Servo motor

Washing machine motor

Vacuum cleaner motor

Power tool motor

-

*with Fan

Cooling fan / others

Please contact us even if your workpiece is not listed here.

Balance measurement and correction can be performed on workpieces with or without wires.

Some images shown here are without workpiece wires.

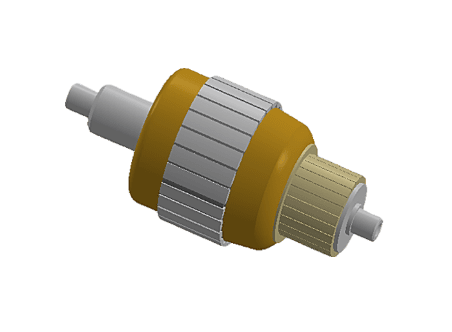

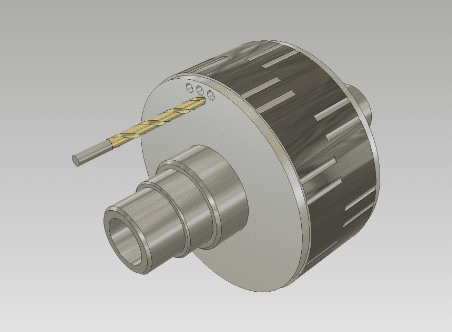

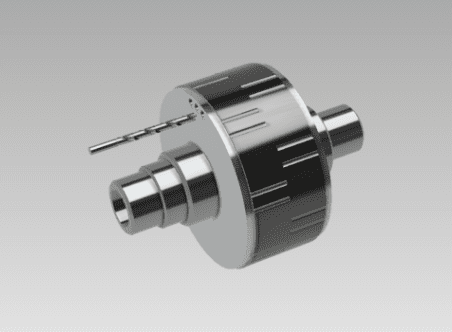

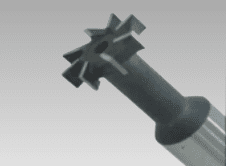

02Example of cutters

We can accommodate your desired correction method for your product.

If not specified, we will suggest appropriate cutters or drills depending on the machine cycle time and the amount of balance correction required.

Drill

Drill makes holes around the perimeter of the workpiece or side plates.

The amount of balance correction is controlled by the depth and number of holes.

Accuracy: Good (If it is required to avoid a certain shape such as a hole that is originally there, the accuracy of balance correction will be limited)

Time: Long (more time is required because the number of holes increases as the required correction amount increases)

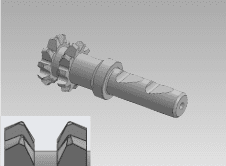

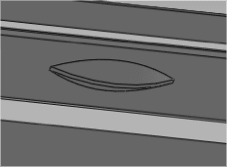

V cutter

The V-cutter makes a depth/length correction at the center of the workpiece core pack for left and right planes.

Cutting is performed per individual core pack.

Accuracy: Good (fine balance amount can be adjusted)

Time: Long (less correction amount at a time, more time consuming as required correction amount increases)

-

-

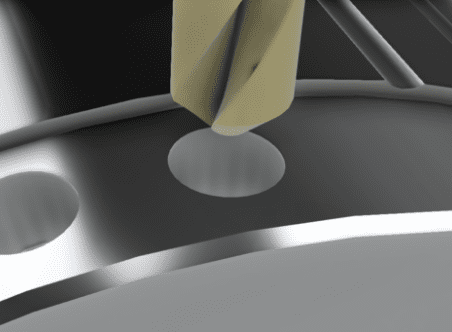

Cutting image

-

Cutting mark

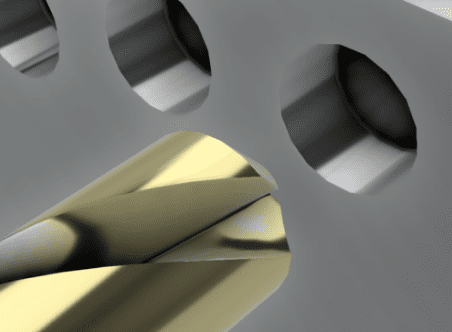

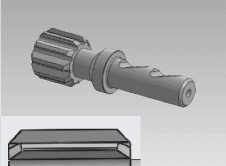

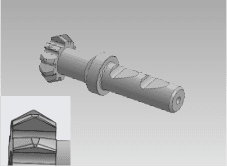

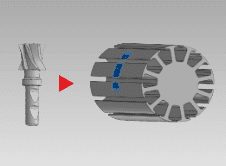

R cutter

The R-cutter makes a correction across the groove of the workpiece core.

Accuracy: Good (may vary depending on the shape of the workpiece core groove)

Time: Short (more correction amount at a time, fast even when the required correction amount is large)

-

-

Cutting image

-

Cutting mark

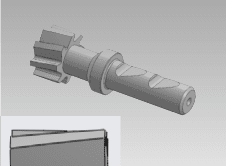

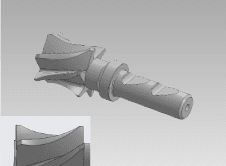

Other cutters

Depending on the customer's specifications for balance correction, we can also use cutters such as V-shaped double blades.

It may also be possible to correct the workpiece balance with a commercially available T-slot cutter.

In the image above, a metal part is cut, but it is possible to make the correction on other materials as well.